The Benefits of Using Precision Tool Vises

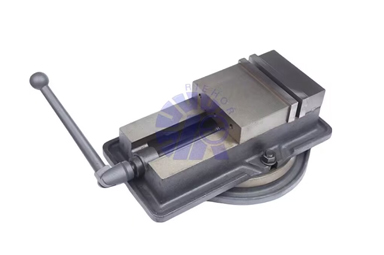

Precision tool vises are essential fixtures used in various machining operations, such as milling, drilling, and grinding. These vises provide a secure and precise clamping mechanism for holding workpieces, offering several benefits that contribute to improved accuracy, efficiency, and overall productivity. Here are the key advantages of using precision tool vises:

Enhanced Workpiece Stability: Precision tool vises are designed to securely hold workpieces in place during machining operations. The vises feature strong and rigid construction, ensuring minimal workpiece movement or vibration. This enhanced stability is crucial for achieving accurate and precise machining results, as it reduces the risk of dimensional errors and surface imperfections.

Precise Positioning: Precision tool vises offer precise positioning capabilities, allowing operators to accurately align workpieces relative to the machining tools. The vises typically incorporate calibrated scales or indicators that enable fine adjustments and repeatability. This level of precision ensures consistent machining outcomes and facilitates the production of high-quality parts.

Versatility: Precision tool vises are versatile fixtures that can accommodate a wide range of workpiece sizes, shapes, and materials. The jaws of the vises can be adjusted to fit different workpiece dimensions, enabling flexibility in machining operations. This versatility eliminates the need for multiple vises or clamping devices, reducing setup time and improving overall operational efficiency.

Time and Cost Savings: Precision tool vises enable faster and more efficient workpiece setup, reducing machining time and labor costs. The vises feature quick and easy clamping mechanisms that securely hold the workpieces in place, minimizing the time spent on manual tightening or adjustments. Additionally, their precise positioning capabilities eliminate the need for repeated measurements and trial-and-error setups, further saving valuable production time.

Improved Machining Accuracy: The stability and precise positioning provided by precision tool vises contribute to improved machining accuracy. With workpieces securely held in place, the vises minimize the chances of dimensional errors, misalignments, or unwanted movement during cutting or drilling. This accuracy is vital for achieving tight tolerances and ensuring parts conform to specified design requirements.

Repeatable Results: Precision tool vises offer repeatable clamping and positioning, ensuring consistent machining results for multiple workpieces. Once a setup is achieved and verified, the vises can be easily replicated, allowing for efficient batch production. This repeatability is particularly beneficial in industries where consistency and conformity to specifications are critical, such as aerospace, automotive, and medical device manufacturing.

Increased Operator Safety: Precision tool vises provide a secure clamping mechanism that reduces the risk of workpiece movement or ejection during machining. This enhances operator safety by minimizing the potential for accidents or injuries caused by unexpected workpiece dislodgement. The vises also feature ergonomic designs that prioritize operator comfort and ease of use, further enhancing safety in the workplace.

Compatibility with CNC Systems: Many precision tool vises are designed for compatibility with computer numerical control (CNC) systems. These vises can be easily integrated into CNC machining centers, allowing for automated operations and improved productivity. The vises can be programmed to move and position workpieces precisely, facilitating unmanned or lights-out machining processes.

Extended Tool Life: Precision tool vises contribute to extended tool life by reducing tool wear and improving cutting tool performance. With stable workpiece clamping, the cutting tools can operate under optimal conditions, minimizing tool deflection and vibration. This prolongs tool life, reduces the frequency of tool replacements, and lowers overall tooling costs.

评论

发表评论